When Texans start shopping for a whole home generator, the first conversation is almost always about the box sitting outside. How big is it? How loud is it? Is this the one that’ll run the AC, the fridge, and still let me microwave something during a storm?

Nobody gets excited about the electrical panel. It’s just that gray metal door in the garage you only open when a breaker trips.

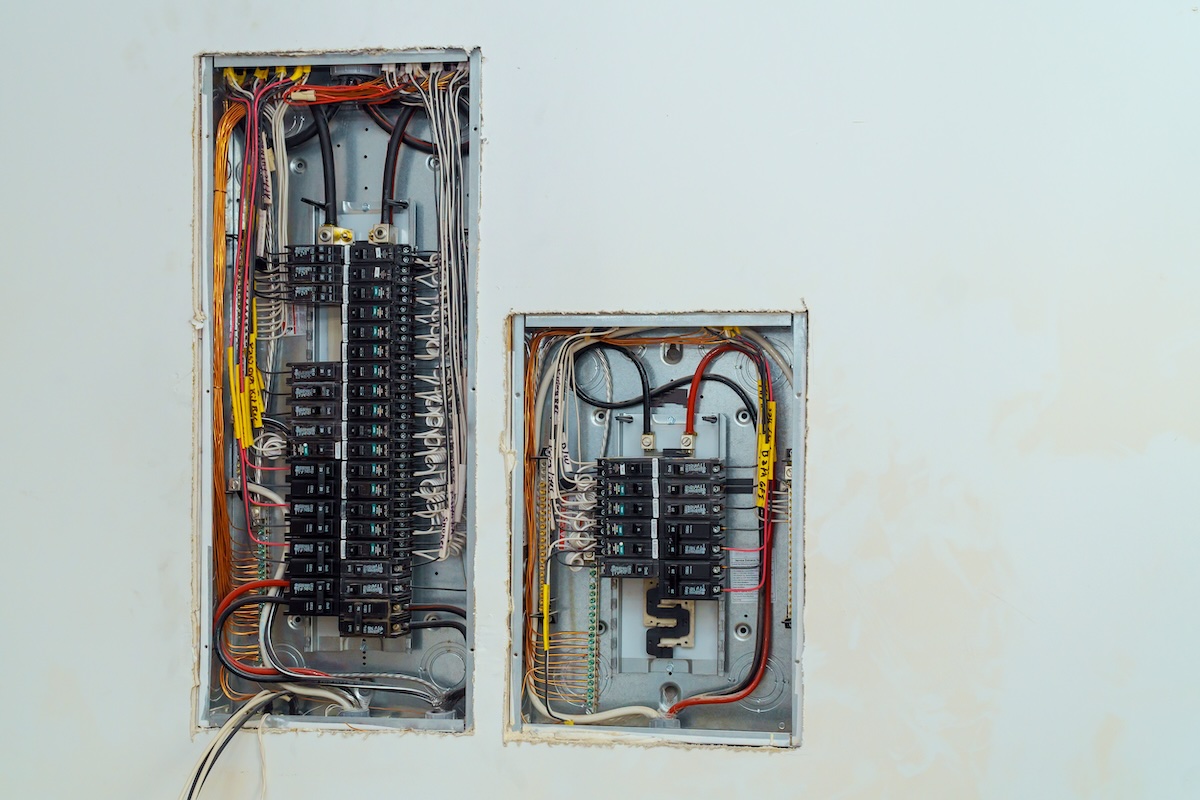

Then the installer takes that cover off, leans in, and goes quiet for a second… and that’s usually when the real conversation starts.

Here in Harris County, backup power can feel a lot less theoretical than in many other parts of the country. Storm season rolls in with heavy rain bands, wind that rattles fences, and transformers popping somewhere down the block. A few months later, a rare freeze can push demand to the edge again, heaters running nonstop while the grid strains under load. Power outages in Houston don’t follow one pattern. Sometimes it’s a hurricane pushing through the Gulf. Sometimes it’s an ice event that wasn’t supposed to be a big deal. In both cases, the generator outside gets the attention, but the panel inside is what determines whether your home rides through those outages smoothly or stumbles the moment power shifts sources.

All that is to say that if you’re prepping your home for standby generator installation in Houston, one of the first things that has to be answered—before permits, before gas lines, before brand debates—is whether your existing electrical panel can actually handle it. That answer comes down to service size, the condition of the panel itself, how your home’s loads are distributed, and how the transfer equipment will tie into what’s already there.

This isn’t about someone trying to sell you a new panel just because it looks newer or more impressive. It’s about whether the backbone of your home’s electrical system is built to safely accept a backup power source when the grid goes down.

What Your Electrical Panel Does During an Outage

In normal conditions, your panel distributes utility power to each branch circuit in your home. During an outage, a standby generator paired with an automatic transfer switch disconnects the utility feed and reconnects your home to generator power.

That transfer has to be precise. The panel must handle the changeover cleanly, without backfeeding, overloading, or creating unstable voltage conditions.

The generator does not simply “plug into” your panel. It becomes a second power source routed through transfer equipment that interacts directly with the panel’s bus bars and breakers. If the panel is outdated, undersized, overcrowded, or mechanically worn, it can become the weak point in the system.

Service Size

100 Amp vs 200 Amp and Beyond

In Houston, most newer homes have 200-amp service. Older homes often have 100-amp service, and some mid-2000s builds sit somewhere in between.

Service size is important because it determines the maximum load the system is designed to carry. A standby generator must be sized according to the home’s calculated load, and the panel must be rated to safely distribute that load.

If you have a 100-amp panel and plan to install a generator capable of running central air, electric water heater, kitchen appliances, and lighting simultaneously, the math may not work. Even if the generator can produce the power, the panel may not be rated to manage it safely.

A proper load calculation looks at square footage, HVAC equipment, major appliances, electric vehicle chargers, pool pumps, and any additional high-demand equipment. That calculation determines both home generator size and whether the existing service capacity is appropriate.

Sometimes the generator size drives the panel upgrade. Other times, the panel upgrade makes it possible to install the generator you actually want.

Panel Age and Mechanical Condition

Not all panels age gracefully. Breaker contact tension weakens over time. Bus bars develop pitting and corrosion, especially in humid Gulf Coast environments. Some older panel brands are known for internal failure risks under load stress.

When you add a generator, you introduce repeated transfer events and potential surge conditions. That exposes weaknesses.

If a panel is more than 25 to 30 years old, shows signs of overheating, has double-tapped breakers, or feels physically crowded, upgrading may be the safer long-term decision. A standby generator is meant to add resilience to your home. Installing it on top of a panel with known reliability concerns defeats that purpose.

There’s also a practical consideration: many older panels simply don’t have physical space for the required generator breaker or transfer switch integration.

Automatic Transfer Switches

The transfer switch is the traffic controller between the utility and the generator. It either sits between the meter and the panel or integrates directly into the panel depending on the system design. A standby generator installation almost always uses an automatic transfer switch (ATS). The ATS physically disconnects utility power and connects generator power without you touching anything. That’s the standard for whole-home systems.

If your existing panel cannot accommodate a whole-house transfer switch configuration, installers may recommend one of two approaches: replacing the panel entirely or adding a subpanel dedicated to generator-backed circuits.

The choice depends on how much of the home you want powered during an outage.

A true whole home generator setup routes all loads through the transfer equipment. A managed-load system may prioritize major circuits and shed lower-priority ones automatically.

The panel has to support whichever architecture is selected.

What about an Interlock?

Some homeowners in Harris County ask about panel interlock kits. Those are typically used for portable generator setups and require manual operation. Whole-home standby systems instead use automatic transfer equipment designed to switch power sources without user intervention.

An interlock is related to panel and generator integration, but it typically applies to portable generators, not whole-home standby systems with automatic transfer switches.

An interlock is a mechanical device installed inside a panel that prevents the main breaker and a generator backfeed breaker from being on at the same time. It’s a manual safety solution. You have to:

- Roll out the portable generator

- Start it

- Flip breakers manually

- Slide the interlock plate

- Switch over loads intentionally

It’s safe when installed properly and permitted, but it’s not automatic and not typical for permanent standby generator systems.

An interlock can be a practical solution for occasional outages if you’re comfortable managing the process yourself and being present every time the power drops. A whole-home standby generator with an automatic transfer switch operates differently. It monitors utility power continuously, starts within seconds of an outage, isolates the grid automatically, and restores power without you stepping into the garage or pulling out extension cords. During a hurricane or a middle-of-the-night grid failure, that’s the difference between manual load juggling and home power continuity. If the goal is hands-off operation, automatic transfer equipment is in a different category of system design.

Subpanels – When Do They Make Sense?

In some homes, especially those with 100-amp service or limited panel space, installing a subpanel can be a practical solution.

A subpanel allows specific circuits—often HVAC, refrigeration, lighting, and essential outlets—to be routed through generator-backed distribution while leaving nonessential loads on the main panel.

This approach can avoid a full service upgrade while still providing reliable outage protection.

However, subpanels are not a workaround for undersized service. If the incoming service conductors and main breaker are inadequate for the total calculated load, splitting circuits into a subpanel does not increase capacity. It simply reorganizes distribution.

When a Full Panel Upgrade Is the Right Move

Sometimes upgrading to a 200-amp panel is the cleanest path forward. Especially in Texas homes adding EV chargers, tankless water heaters, pool equipment, or expanded HVAC systems.

A generator installation often reveals that the electrical system was already near its practical limit.

Upgrading the panel before installing the generator ensures the entire system—from utility feed to branch circuits—is aligned in capacity and safety rating.

It also improves resale value. Buyers increasingly look for modern electrical infrastructure, particularly when standby generators are installed. A new panel signals long-term reliability.

Gas Supply & Electrical Coordination

Panel capacity is only part of the equation. Standby generators typically run on natural gas or propane, and gas line sizing must match generator demand.

If you upgrade to a larger generator due to panel or load calculations, the gas infrastructure must also be evaluated. Undersized gas lines can cause startup failure or voltage instability under heavy load.

The electrical and fuel systems must be designed together. One without the other creates performance problems that only show up when the power actually goes out.

Panel Inspection Is Part of Every Proper Generator Installation

Before a whole-home standby generator is installed, the electrical panel has to be evaluated. A standby generator ties directly into your home’s service equipment through a transfer switch. That means the installer has to:

- Verify your service size (100A, 150A, 200A, etc.)

- Inspect the panel’s physical condition

- Confirm available breaker space

- Check grounding and bonding

- Run an actual load calculation

- Make sure the panel is compatible with the transfer equipment

The installer needs to confirm service size, inspect breaker condition, verify grounding and bonding, check available space for transfer equipment, and run a proper load calculation. None of that can be completed from a phone call or a driveway conversation. At some point before whole home generator installation, the panel has to be opened and reviewed.

Without inspecting the panel, Houston electricians can’t size the generator properly, can’t quote the job accurately, and can’t pass inspection with the city. So if someone is prepared to install a whole-home generator without ever opening your panel and reviewing your service details, that’s a red flag.

In many Houston-area homes. especially those built within the last 15 to 20 years with 200-amp service—the existing panel is fully capable of supporting a standby generator without major modification. In other homes, the inspection reveals stress points.

The Practical Answer

So can your existing electrical panel handle a standby generator?

In many homes built within the last 15 to 20 years with 200-amp service and well-maintained panels, the answer is yes.

In older homes with 100-amp service, aging breaker technology, or expanded electrical demands, the answer is sometimes no—or not without modification.

The only way to know is through a proper load calculation and panel inspection by a licensed electrician who understands both whole home generator installation and residential service architecture.

A standby generator should make your home more resilient. The panel is the gatekeeper that determines whether that resilience is engineered correctly or improvised.

When done properly, the integration feels seamless. The power goes out, the generator starts, and life continues inside the house without disruption. That kind of reliability begins with the panel—long before the generator ever fires up.